Shaft Inspection

VICIVISION manufactures the world’s most advanced optical, non-contact shaft measuring machines and quality control systems for the improvement of efficiency in production at their state-of-the-art facility in Rimini, Italy.

Techno Series

The wide measuring field from 40 to 180mm in diameter and 300 to 1250mm in length make the compact, yet ergonomic and robust, Techno systems suitable and adaptable to both your current and future demands. All systems provide micron-precision performance in terms of accuracy and repeatability.

Technical

Diameters from 40-180 mm

Lengths from 300-1250mm

Max. loadable sizes up to 1300xØ240 mm, 60Kg

Accuracy: 1.5+D/100 μm, 4+L/100 μm

Repeatability: Ø0.3 μm / 1.2 μm

M1

Compact and ergonomic, M1 is the ideal tool to flank multi-spindle lathes or sliding head lathes. From simple fittings to small shafts measuring up to Ø60×300 mm.

Technical

Measuring field: 300xØ60 mm

Max. loadable sizes: 315xØ120 mm, 10Kg

Accuracy: 2+D/100 μm, 5+L/100 μm

Repeatability: Ø0.4 μm / 3 μm

M2/M3

M2 and M3 were born to assist in production. Designed not only to measure large shafts, they can also capture minute details such as bevels and small radii. These are top end machines measuring from small components to 140x900mm shafts with an increased load capacity that allows elements up to 250 mm in diameter to be positioned.

Technical M2/M3

Measuring field: 600xØ140 mm / 900xØ140 mm

Max. loadable sizes: 625xØ240 mm / 925Dx240 mm, 30Kg

Accuracy: 2+D/100 μm, 5+L/100 μm

Repeatability: Ø0.3 μm / 1.2 μm

MTL X5

MTL X5 is an optical measuring machine specifically designed to measure micro-mechanical parts, dental implants, watch parts and micro-parts in general.This high resolution machine, one of a kind in its category, detects even the smallest details. Measuring tools designed for every need: static measurements, hexagon and threads analysis.

Technical

Measuring field: 100xØ16 mm

Max. loadable sizes: 270xØ90 mm, 3Kg

Accuracy: 2+D/100 μm, 5+L/100 μm

Repeatability: Ø0.4 μm / 3 μm

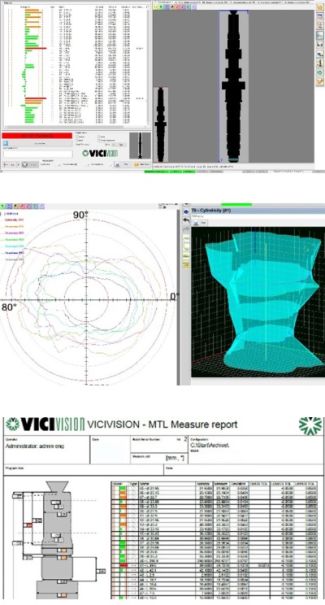

MTL Measuring Software

The brand new MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc.

New automatic features help the operator to get measurements: self-programming, automatic loading of the part program, step by step assisted programming, DXF comparison.

The software allows the operator to print or export complete and custom pdf measurement reports. Results of measurements on histograms for immediate consultation.